Contents

What Is A Fuel Rail Pressure Sensor?

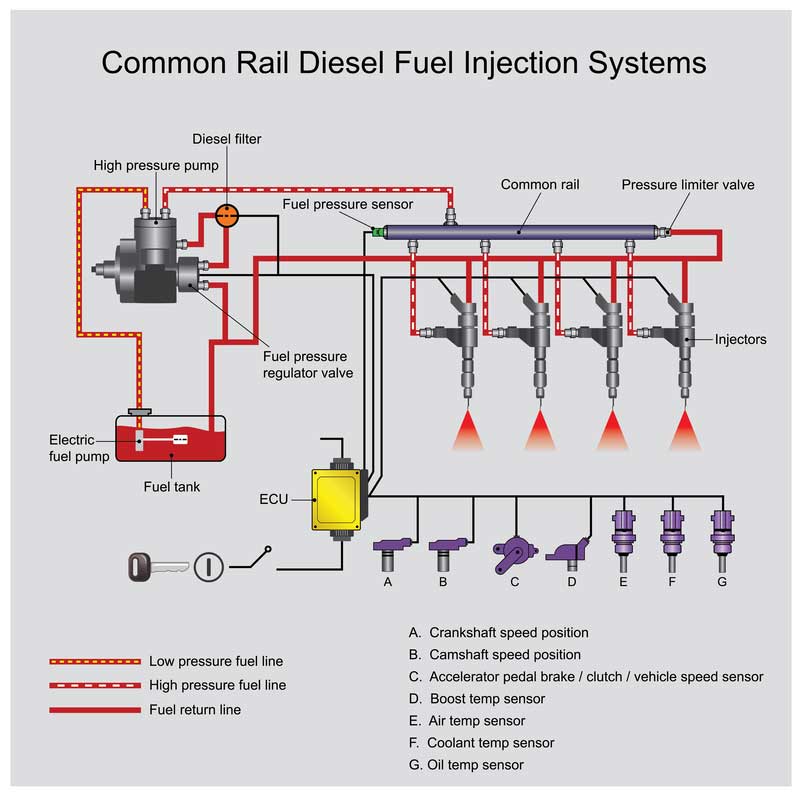

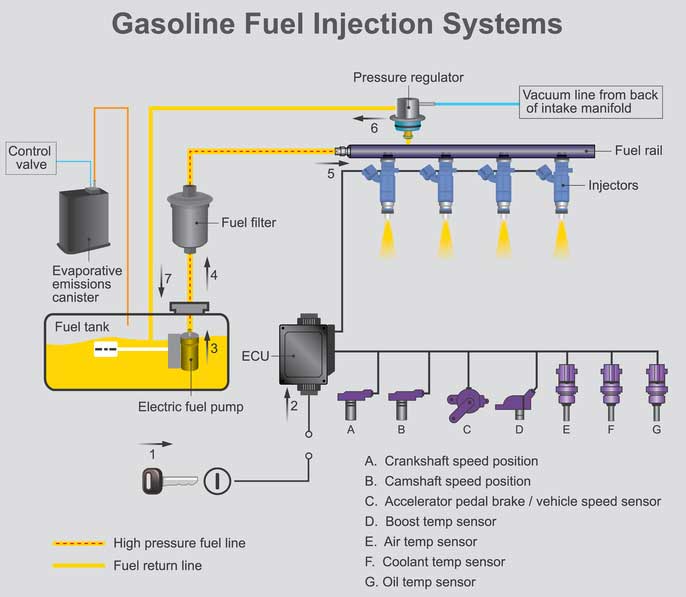

An engine is a crucial part of any vehicle. Internal combustion engines today use petrol or diesel as fuel. These engines have a fuel pressure sensor in the rail known as the fuel rail pressure sensor.

It makes up a vehicle fuel system, and it’s designed to monitor the fuel’s pressure inside the rail. Once the sensor obtains the pressure information, it sends it to the Electronic Control Unit (ECU) which makes the needed adjustments to the vehicle’s fuel and timing.

The sensor measures the fuel pressure quickly and gives high-accuracy results. However, if it sends the wrong information, it can interfere with the vehicle’s performance. Learn more from this guide about this sensor, its characteristics, and other things.

Where Is The Fuel Rail Pressure Sensor Located?

The fuel rail sensor is usually mounted at the fuel rail near the vehicle’s intake manifold, regardless of the fuel mechanism of the vehicle. However, some manufacturers mount it on the fuel line. But this is very rare. Check your vehicle’s intake manifold to see the fuel rail, pressure sensor, and injectors.

How Does this System Work?

The sensor comes with a sensitive element inside. Plus, it also includes an integrated electronic circuit. It also features a channel that allows fuel to enter its body and then to the sensitive element.

The pressure is converted into electrical voltage and amplified by the present electrical circuit through this action. Then, electrical contacts send it to the ECU for the necessary adjustments.

Note that this sensor is a resistive strain and operates on the piezoresistive effect. The effect says that conductors have different electrical resistance abilities depending on their longitudinal deformation.

- The main channel, where fuel enters under pressure;

- The body that contains the sensitive element and the electronic circuit;

- The electrical connector.

The sensor’s sensitive element contains various silicone-based semiconductor films. Thus it compensates for the temperature effects on the rail sensor. The sensor is always active, and it should always be powered from a voltage source of +5V.

If you look at the rail sensor, you will notice the ground, supply, and output voltage pins. The sensor generates voltage depending on the fuel pressure the rail receives. Mostly, the voltage is usually between 0-70Mv.

Once the pressure is recorded, the electrical circuit integrates and evaluates the information before transforming it into a voltage of 0.5-4.5V. The sensor uses a 0-1800 measuring bar range. The system’s measuring range should always give accurate readings; otherwise, it may interfere with the injection system.

The average injection pressure, which is the measured pressure minus the actual value, should not be higher than ± 2%. The ramp’s fuel pressure can be 280 and 1800 bar at idle and maximum load. But, this will depend on the type of injection system you have and its injection pressure.

You should also note that the rail sensor generates signals that are part of the closed injection loop. Once you press the gas pedal, the ECU quickly calculates the fuel amount your engine needs to obtain the correct torque. This amount is obtained by calculating the pressure level at which the fuel rail must be.

The pressure valve on the fuel rail controls the pressure. The ECU controls this valve based on the fuel pressure signals it receives from the rail sensor. Then, it calculates the pressure inside the rail.

Technical Characteristics Of A Fuel Rail Pressure Sensor

The supply voltage is – 5 ± 0.25, the temperature range is – 40° C to +130° C or -40° F to +266° F. Also, the measuring range is 0 bar to 1800 bar, and the response time is 2ms.

Symptoms Of A Bad Fuel Rail Pressure Sensor

A faulty sensor is risky as it interferes with the engine’s operation. Note that the engine will get the wrong fuel pressure readings regarding the rail valve. Therefore, instead of running in the closed loop, the ECU will control the rail pressure to open the loop.

Many vehicle owners have complained about fuel pressure sensor problems. Most of these issues are caused by the fact that this sensor operates in high temperatures.

But a faulty sensor does not mean that you change the entire rail system. You only have to replace the sensor and repair the system, which can take approximately 15 minutes or so. Here are some signs that your sensor has a problem.

1. The engine does not start or has a difficult start

If your engine does not start, it could be that you have a defective fuel pressure sensor. Usually, the engine will start hard a few times and then refuse to start completely.

Note that a faulty pressure sensor interferes with the fuel amount the ECU sends to your engine. Without the correct fuel amount, you’ll have trouble starting your vehicle.

2. Increased fuel consumption

When your fuel rail pressure sensor is faulty, the ECU will not know the correct fuel amount to deliver to the rail. Therefore, it could send more or insufficient amounts.

3. Check engine light is on

Vehicles have an engine control system that detects issues affecting the engine in one way or the other. If any issues are present, it activates the check engine warning light.

The light doesn’t always mean there’s a problem with your engine. But it indicates that there is something else interfering with the proper functioning of the engine.

A diagnostic scan tool can often tell you whether the issue is caused by a defective rail pressure sensor. OBD2 codes like P0190, P0191, P0192, P0193, and P0194 mainly indicate that this sensor has a problem.

4. Weak acceleration power

If your vehicle has trouble accelerating, you may want to check its rail pressure sensor. A defective pressure sensor affects the signals the ECU transmits to the fuel system. Thus, it may send wrong information as it doesn’t know the correct levels of the demands placed on the engine.

5. Engine stalling

This usually happens when driving, but it can also happen when your car is at rest. It often indicates a problem with the fuel rail sensor. A stalling engine makes driving very difficult and potentially dangerous. Please, take your vehicle to the nearest garage if you are experiencing this problem.

6. You feel like you’ve lost a lot of engine power.

If you notice significant engine power loss, intermittent or continuous, then you should consider checking the fuel rail pressure sensor.

How Much Does Fuel Rail Pressure Sensor Replacement Cost?

The amount varies depending on the car’s make and model. But on average, expect to spend between $200-$400 for a new sensor and the replacement.

Sensors are usually sold at $50-$120. Then the mechanic charges $150-$280. Where you decide to take your car also influences the total amount you’ll spend.

Conclusion

Fuel rail pressure sensors play a crucial role in how a vehicle’s engine functions. For this reason, they must always be in excellent working conditions to give accurate information. Be on the lookout for the above signs and if you notice them, please take your vehicle to a mechanic.

Comments are closed.